The most fundamental aspect Additive Manufacturing is the term used by industry professionals for the method of making an object that is three dimensional from the digital model known as CAD (Computer Aided Design) model which is accomplished by introducing layers of materials.

In contrast to subtractive manufacturing which removes material AM constructs an object by starting from scratch. The seemingly straightforward change in method opens up many possibilities.

The procedure begins with the creation of a 3D digital image and is cut into hundreds or thousands tiny horizontal cross sections using special software. A computer then scans the cut file and deposit and fuses or curing the material layer after layer exactly according to the blueprint of every cross section until the final model is completed.

Layer by layer is the fundamental thread which binds many different techniques. To help bring order to the diversity of these technologies international standard organisations such as ASTM as well as ISO have organized Additive Manufacturing processes into seven distinct classes.

Knowing these seven pillars is vital to fully comprehending the capabilities and scope of technology of the present. The area of Additive Manufacturing is more than a single thing it is a collection of closely related and distinct manufacturing techniques.

The Seven Pillars of Additive Manufacturing Technology

The seven categories of process defined by ASTM F42 offer a concise structure to understand the many methods of building objects by adding. Each technique has distinct strengths limitations materials compatibilities and the best uses.

1. Vat Photopolymerization

It was the first commercially profitable Additive Manufacturing technology which was developed in the 1980s. Its renowned for creating parts that have exceptional surface finishes as well as fine details.

- The way it works: A build platform is submerged within a vat of resin that is liquid. The lighting source (typically an UV laser or digital projector) can be used to selectively cure and harden the layer of resin. When one layer has cure the build platform shifts in a slight manner and then it repeats the process. There are two major variations: Stereolithography (SLA) that employs a laser to mark the layers as well as Digital Light Processing (DLP) projecting an image of all the layers at once.

- Ingredients: Photopolymer resins (thermosets). These range from regular plastics to castable flexible or high temperature special resins.

- Application: High fidelity prototypes models for medical and dental and jewelry casting designs and precise visual models.

2. Material Jetting

Material Jetting works in a similar way as the 2D inkjet printer however it layers layer upon layer to form an object that is 3D. Its prized because of the ability to produce amazingly realistic multi material and multi color components.

- What it does: Print heads with hundreds of tiny nozzles release droplets of photopolymer onto the build platform. The droplets are immediately cured with the UV light traveling along that print head.

- Materials The photopolymer resins. One of the main advantages is the capability to use a variety of different materials with various print heads within the same mold allowing to create parts that have different colors transparency and shore the hardnesses.

- applications: The most realistic fully colored prototypes and anatomical models to aid in surgical plan tools for injection molding and precise concept models. This kind of Additive Manufacturing excels when it comes to creating products that look as and feel similar to what they will be in the end.

3. Binder Jetting

Binder Jetting is a process that can be used in a variety of ways which can be used with an array of different materials like metals sands and ceramics. Its renowned for its fast capacity and speed which makes it ideal to produce large quantities.

- The way it works: A recoating arm disperses a thin layer powdered materials over the build platform. The print head moves over the powder and is selectively depositing drops of a liquid binding agent that “glue” the powder particles to form layers. The platform is then reduces and a new layer of powder gets spread over the previous one and then the process is repeated. Following printing the piece remains in a fragile “green” state and must undergo post processing steps like the sintering process infiltration or curing to attain the strength it needs to be.

- Ingredients: Sand (for casting molds) and metals (stainless steel Inconel) and ceramics.

- Application: Large sand casting molds and cores for foundries inexpensive metal prototypes and ceramic models that are full color. Potential for large scale Additive Manufacturing of metal pieces is an essential reason for this type of technology.

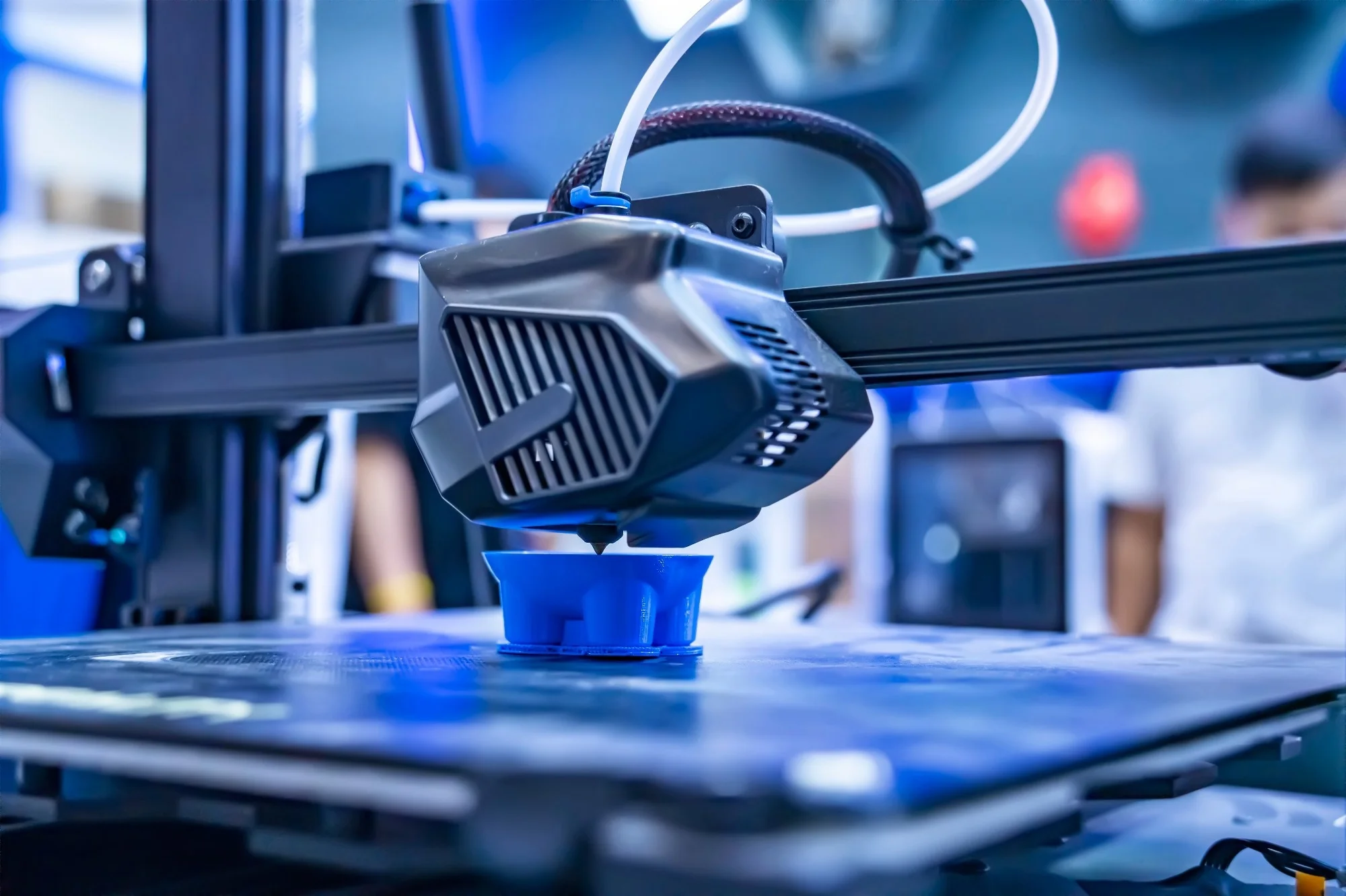

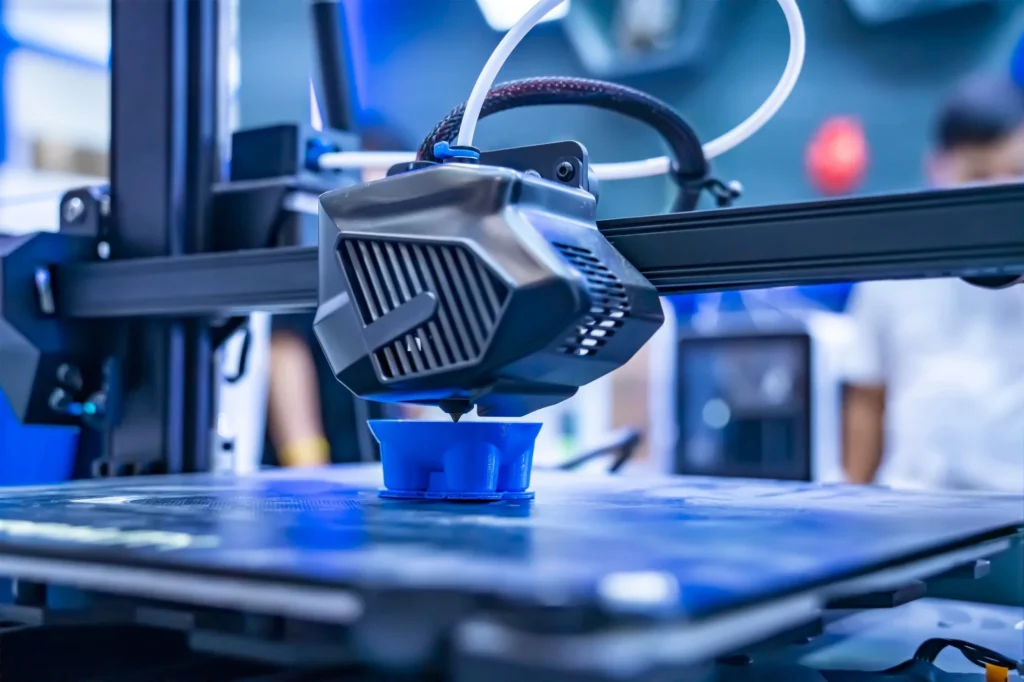

4. Material Extrusion

It is by far the most known and easily accessible type that is available in Additive Manufacturing mostly due to the emergence of low cost desktop printers. The process is officially referred to by the name of Material Extrusion with Fused Deposition Modeling (FDM) being the trademarked name of Stratasys.

- What it does: A spool of thermoplastic filament solid is fed through an extruders. The extruder nozzle melts the filament before it puts it into a building platform. Then it traced the entire cross section of the build platform. The filament cools and then solidifies in a flash before fusing with the layer beneath.

- Materials There are a variety of thermoplastics. These include PLA ABS PETG and high performance polymers such as PEEK as well as ULTEM. Composite filaments that are reinforced with glass fiber or carbon fiber are also popular.

- applications: Early stage concept models and functional prototypes. They also include manufacturing tools (jigs as well as fixtures) as well as end of use components that are low stress for applications. High quality industrial material Extrusion is the most reliable tool in the modern age of Additive Manufacturing.

5. Powder Bed Fusion (PBF)

Powder Bed Fusion encompasses a set of Additive Manufacturing processes which use a heat source typically the laser or an electron beam to selectively melt or fuse regions of a mattress. Powder Bed Fusion is the most popular technique for making high strength practical metal parts and polymer components.

- What it does: A layer of fine powder is spread over the build platform within an enclosed chamber. Lasers with high power or an electron beam scans the entire cross section of the layer causing it to melt and bonding the powder particles. The platform is then lowered another layers of powder are sprayed then the process is repeated.

- Key Variations:

- Selective Laser Sintering (SLS): Uses the laser to melt Polymer Powders (like nylon).

- Direct Metal Laser Sintering (DMLS) (also known as Selective Laser Melting (SLM): Utilizes lasers to completely melt the metal powders.

- Electron Beam Melting (EBM): Uses an electron beam within an atmosphere of vacuum to melt metal powders. It is ideal for high temperature and reacting substances.

- Material: Polymers (primarily nylons) and metals (titanium and aluminum) stainless steel Inconel and cobalt chrome).

- Applications It is the most reliable tool for Additive Manufacturing. Aerospace parts Medical implants aerospace components intricate manufacturing tools and top quality high performance components.

6. Directed Energy Deposition (DED)

Directed Energy Deposition is often employed to repair or add materials to components already in use creating the hybrid process of manufacturing. It is well known for its fast deposition rate and the ability to make massive components.

- The way it works: A nozzle usually installed on a multi axis robotic arm deposits hot material on the surface. The substance (either in powder or wire form) is then fed through the nozzle before being melted with the energy source focused (a laser beam electron beam or plasma arches) when it is being deposited.

- Materials Nearly exclusively metals that include titanium as well as aluminum steel and a variety of superalloys.

- applications: Repairing high value metal components like turbine blades and molds incorporating features into the existing structures or creating massive structural parts for defense and aerospace. This is a vital technology that is essential to the maintenance repair and overhaul (MRO) segment in Additive Manufacturing.

7. Sheet Lamination

It is among the less well known Additive Manufacturing processes with unique uses. It creates items by stacking and gluing thin sheets of materials.

- The way it works: A sheet of material is placed on a construction platform and bonded with the substrate below by the ultrasonic or adhesive. The laser or the blade creates the outline on the surface. The extra material is then removed before a fresh sheet is inserted.

- Material: Paper plastics Metals composites and paper in sheets.

- Application: Creating full color prototypes (using paper) creating large scale concept models as well as embedding electronics or sensors in layers.

Materials in Additive Manufacturing: The Expanding Palette of 2025

The full potential of Additive Manufacturing can only be realized by advances in materials research. By 2025 the selection of materials that can be printed has widened significantly going well beyond the basic plastics and incorporate materials that are able to are able to meet the rigorous demands of the most demanding industries.

Polymers

- Thermoplastics The most used in Material Extrusion thermoplastics like PLA ABS and PETG are still popular as prototyping materials. However the most significant development is happening in high performance polymers such as PEEK PEKK and ULTEM with high durability chemical resistance and high temperature tolerance. These make the ideal material for aerospace and automotive parts that require a lot of end user.

- Thermosets Utilized for Vat Photopolymerization as well as Material Jetting. The types of resins have excellent surface finishes and fineness. The advancements in technology have resulted in the creation of durable tough resins which mimic the characteristics of engineering plastics in addition to specific biocompatible flexible and casting compatible material.

Metals

Metal Additive Manufacturing is perhaps the most significant field of technology. Powder Bed Fusion (DMLS/SLM EBM) and DED are the main methods.

- Titanium Alloys Strong light and biocompatible the titanium (e.g. Ti64) is an important component in the aerospace industry for parts such as brackets the structural airframe as well as in the field of healthcare for customized implantable orthopedic devices.

- Aluminum Alloys They are used in applications where a high strength to weight ratio is required like in motorsports automotive and in heat exchangers.

- Nickel Superalloys Materials such as Inconel 718 are crucial for aerospace with high temperature applications like components of jet engines (fuel turbine blades nozzles).

- Steels Steels made of stainless steel and steels for tooling are extensively employed to make strong injection molds tooling that have conformal cooling channels and parts for industrial machinery.

Ceramics

Ceramic Additive Manufacturing is complicated due to the materials fragility but it has huge possibilities. Vat Photopolymerization and Binder Jetting (using clay based resins) are the most common processes. After printing elements must be sintered by an oven to reach the full the density.

- Application: Technical ceramics like zirconia and alumina can be used in high temperature electrical insulators. They also serve as components for chemical processing as well as dental implants biocompatible.

Composites

Additive Manufacturing is specifically suited for creating composites with specific characteristics. It is typically accomplished by strengthening thermoplastic filaments using chopped and continuous fibers (carbon glass glass and Kevlar). The result is parts that are extremely light yet sturdy and robust which makes the ideal replacement for metal for many different uses.

From Design to Product: The Additive Manufacturing Workflow

The process of converting a digital concept to an actual object by Additive Manufacturing follows an unwavering digital track.

3D Design (CAD): It begins with a 3 D model that is created using the CAD program. One of the major paradigm shifts in this area involves “Design for Additive Manufacturing” (DfAM) in which designers use the unique technologys capabilities to design intricate light weight and integrated components that are difficult to create using traditional techniques.

Formatting Files (Slicing): The models CAD data is exported generally in a STL or 3MF file format. The file is loaded to “slicing” software. The slicer converts the model in G code which is a specific set of instructions to the AM machine. This is where the user determines the most important parameters such as the height of the layer the orientation of print and the design of the necessary supports.

The Printing Process The G code gets sent directly to an Additive Manufacturing machine. The operator sets up the machine for printing by taking the materials into the machine and ensuring that the platform for building is properly calibrated. The process of building then goes on smoothly layer by layer that can last anywhere between a couple of hours and many days depending on the dimension and the degree of complexity of the component.

Post Processing The majority of the components come out of the printer and are ready to utilize. Post processing is an essential and frequently labor intensive step. The most common steps are:

Support Removal Support structures that are sacrificial used to secure overhangs throughout construction should be removed with care.

Cleansing: Removing excess powder (in PBF) or resin (in SLA).

Sintering and Curing Additional heat treatment could be necessary to obtain ultimate material characteristics.

Surface Finishing steps like sanding polishing bead blasting or even machining could be required in order to attain the ideal surface finish and the dimensional precision.

The Transformative Impact of Additive Manufacturing Across Industries

by 2025 Additive Manufacturing is no longer just a marginal technology but an integral element of the production system in many important sectors.

Aerospace and Defense

Aerospace was a pioneer in the field and is still the main driver for innovations in the field of metal Additive Manufacturing.

- The use of lightweighting AM permits the development of “generatively designed” organically formed parts that possess similar strength to traditionally machined components but at less weight. This is crucial to improve fuel efficiency and efficiency.

- Part Consolidation A complicated assembly comprising many parts may be printed and redesigned as one intricate component. It reduces the weight removes the possibility of a failure point and streamlines supply chains. This is the GE Catalyst engine with hundreds of traditional parts changed by a small number of printed parts It is a classic instance.

- Rapid Tooling and MRO The companies utilize AM to create quickly unique fixtures jigs as well as tools for their production manufacturing lines. DED is widely used to fix damaged or worn important components and extend the life of their components.

Healthcare and Medical

The capability that Additive Manufacturing to develop solutions that are specific to patients has revolutionized the field of medicine.

- Custom designed implants: Surgeons can use patients CT scan information to create and manufacture perfectly fitting orthopedic implants (hips and knees as well as cervical cages) as well as cervical plates. The porous structures that can be created through AM can also aid in osteointegration (osseointegration).

- Surgical Guides and anatomical Modelling: Realistic patient specific models and guides for cutting surgical instruments can be printed for surgeons to prepare and execute intricate procedures while reducing the times in the operating room and enhancing the patients outcomes.

- Dental applications: From clear aligners and crowns to dentures and surgical guides The dental field has been fully digitalized through Additive Manufacturing.

Automotive

Although it is still used primarily to prototype the automotive industry is quickly adopting Additive Manufacturing for the production of tooling and final use parts.

- prototyping Am is used for creating and testing design prototypes with unbeatable speed.

- Tools: The printing of custom designed jigs or fixtures and injection mold inserts speeds up manufacturing line set up and decreases cost.

- Performance and Luxury Cars: High end and motorsport vehicles use AM for lightweight performance optimized parts where cost is less of a concern. Since costs are decreasing it is leaking into the production of mainstream vehicles.

Consumer Goods

Additive Manufacturing enables large scale customization and allows businesses to provide customized products customers.

- Shoes: Companies like Adidas have utilized AM to develop midsoles that have lattice structure designed to fit an individuals body physical weight and walking style.

- eyewear The frames for glasses that are custom fit can be designed and printed based on 3D images of the head of the customer.

- Jewellery: elaborate and complicated designs difficult to create are printed directly using precious metals.

Key Advantages of Additive Manufacturing

The rapid use of Additive Manufacturing is motivated by an impressive set of advantages which address problems with traditional manufacturing.

- Design Flexibility and Complexity “Complexity is free.” The cost for an additively produced component is determined by the quantity of materials used and not on the complexity of its geometries. Engineers can design high quality precise as well as lightweight components.

- Mass Customization AM allows you to economically create unique and customized components on a large scale ranging including medical implants to consumer products.

- Supply Chain Optimization AM allows on demand and the localization of manufacturing. Instead of sending parts across the world businesses can simply upload a digital document to a printer that is located in the location in the area where the item is required to create the concept of a “digital inventory” and dramatically reduce lead times and cost of shipping.

- Recycling: As an additive procedure AM uses only the materials needed to construct the piece and produces much lesser waste than subtractive techniques.

- Rapid Innovation The capability to move from digital designs to a tangible prototype within a matter of hours or days facilitates faster design iterations and speed up the complete product creation process.

Challenges and Future Directions for Additive Manufacturing

Despite its amazing progress Additive Manufacturing has its own set of challenges to overcome on its journey to become a standard production technique.

Current Challenges

- Speed and Scalability: Although they are getting more efficient however the vast majority of AM methods are slow when compared with mass production methods such as injection molding.

- Quality Assurance and Standardization: Ensuring part to part consistency as well as developing reliable non destructive testing techniques are essential specifically for parts that have been certified in medical and aerospace industries.

- Materials Costs The high performance resins and powders designed for industry Additive Manufacturing are nonetheless significantly more expensive than the traditional ones.

- skilled workforce: Theres an increasing disparity between the capability of this technology and the amount of skilled technicians and engineers on DfAM or AM machine use.

The Future Frontier: Whats Next?

It is predicted that the future for Additive Manufacturing is positive with the focus being in a variety of key areas.

- AI as well as machine Learning: AI is utilized to enhance design (generative design) The monitor prints in real time allowing you to identify mistakes and rectify them as well as process post processing automatically.

- Multi Material and 4D Printing: The possibility of printing with several material simultaneously allows for the development of objects with functions that are graded. Printing with 4D takes this an additional step producing objects that alter form or function depending on the external stimuli (like the presence of moisture or heat).

- sustainability: Research is focused on the development of more sustainable materials that reduce energy usage in printing and making use of AM to create the circular economy by way of repair and recycling.

- Automating and Integrating The factory of the future will have Additive Manufacturing systems completely integrated into digital workflows ranging from process of removing parts and post processing them for quality control. This will create a the perfect “lights out” manufacturing environment.

Building the Future Layer by Layer

Additive Manufacturing has completely transformed from a prototype tool to a cutting edge and mature technology for production. It will be 2025 before it is viewed as an essential driver of innovation sustainability and individualization throughout the worlds industry.

Through removing manufacturers from the rigors that traditional manufacturing has imposed it has created a brand modern generation of products that are stronger lighter and more efficient more than ever. The company is helping people heal with customized implants making transport more eco friendly and also putting customized products in the hands of people.

The problems of cost speed and standardization are still there however the pace of technological advancement is never ending.

The integration of Additive Manufacturing with artificial intelligence cutting edge technology in materials and connectivity are paving the way towards a future in which factories are more flexible and supply chains are much more local and the ability of our creation is only limited by the imagination of our minds.

Techniques of subtractive manufacturing in the past created the world that we have today however the modern additive methods will create the future of the future in a single layer at one at a time. The new era is here and its printing.