Since the beginning of century now electronic components are defined by their rigidity. Silicon chips and the printed circuit board (PCB) as well as the glass display have served as the brittle hard bases of technological revolution that has transformed our lives.

These devices are strong but fragile and are restricted to boxy enclosure of laptops smartphones and TVs. What if electronic devices could be able to break out of the rigidity of this system? Imagine if they were able to stretch bend and adapt to any surface including the most intricate and dynamism based surface human beings: the human body?

Its not an issue that is science fictional idea. By 2025 we are living in an actuality of technology. Welcome to the era of Flexible Electronics. The new field of technology is breaking the traditional boundaries of shape and function.

It weaves the capabilities of computation and sensors directly into the everyday life of us. In lieu of carrying tech around well begin wearing it integrate it and use it through ways which are intuitive seamless and completely personal.

Flexible Electronics are evolving from research labs into mass market products that power everything from the next generation of foldable smartphones and rollable televisions to smart healthcare patches and intelligent textiles.

This guide is comprehensive look at the world of Flexible Electronics in 2025. It will explore the new materials ingenuous manufacturing techniques and revolutionary applications making our future digital pliable.

What Are Flexible Electronics?

The word Flexible Electronics refers to specific class of electronic circuits and devices that are built on pliant conformable or stretchable surfaces. Contrary to conventional electronics made from solid silicon wafers or fiberboards the base of the flexible circuit is material that is bendable or folded twist and even stretched but without compromising its electronic capabilities.

A simple transition from rigid to flexible has significant consequences. This is major change in the way we design the build and then make use of electronic gadgets. It is the aim of creating technologies that are able to adapt to their surroundings and not the other opposite. The field covers range of conformability

- Bendable Electronics devices that bend at specific radius for example an foldable phone or curved display.

- Conformable Electronics Electronic devices that be wrapped around non flat surfaces for example the sensor patch that is applied to the wing of an aircraft or to human arm.

- Stretchable Electronics the most technologically advanced version that can be used to stretch and loosened like rubber bands which allows applications such as electronic skin (e skin) or smart clothes that move in tandem with your body.

It is crucial to differentiate Flexible Electronics from simply “portable” electronics. The smartphone can be carried around however its internal parts are strong and protected with protective case. Truly Flexible Electronics integrate design and functionality by allowing all the components of the device substrate and conductors transistors and more to be able to deform. This is opening up the possibility of new inventions which was impossible to achieve with the planar rigid technologies in the previous. Development of durable Flexible Electronics is an important goal for an array of different sectors.

The Building Blocks of Flexible Electronics: Materials and Components

The power in Flexible Electronics lies in brand new category of components designed to provide physical sturdiness and efficiency. Making flexible circuit means reconsidering each component beginning with the foundation that it is built on to the wires used to transmit current as well as the transistors responsible for processing information.

1. Flexible Substrates: The Pliant Foundation

The substrate serves as the foundational of the layer from which other elements are constructed. For Flexible Electronics the substrate is required to provide support for mechanical as well as electrical insulation while remaining light thin and flexible.

- polymers. It is the most popular class of material. Polyimide (PI) is an all purpose material appreciated for its outstanding thermal stability that allows it to stand up to higher temperatures in manufacturing procedures. Polyethylene Naphthalate (PEN) as well as polyethylene Terephthalate (PET) are cheaper alternative and are widely used in solar displays that are flexible and cells. In ultra thin biocompatible and biocompatibility uses the polymers Polydimethylsiloxane (PDMS) are commonly used due to their incredible flexibility as well as their the softness.

- Ultra Thin glass: Though it seems like an oddity the glass which is dragged to thicknesses under 100 millimeters can become extremely elastic. It provides superior clarity and is great shield against oxygen and moisture and makes it top display material for top of the line displays.

- Paper and Textiles for low cost recyclable or wearable purposes papers and woven textiles are emerging as feasible substrates. Theyre biodegradable and renewable and easily used in packaging or clothing but they do pose problems in the area of roughness on the surface and absorption of moisture. Textiles are an important innovation for clothing friendly Flexible Electronics.

2. Conductive Materials: The Flexible Wires

The stray copper lines of conventional PCB need to be replaced by conductors that are able to withstand repeated bends and stretching.

- Conductive Inks These are the bloodline printing Flexible Electronics. Inks contain conductor nanoparticles or flakes of copper silver or carbon that are suspended in solvent. These are printed on an uncured substrate in order to make flexible conductive pathways.

- Conductive Intrinsically Polymers Polymers like PEDOT are intrinsically conductive and translucent which makes them perfect for use as electrodes that are transparent on flexible touch screens as well as OLEDs.

- Nanomaterials:

- Metal Nanowires grid of copper or silver nanowires is able to be coated with substance to form clear and conductive layer which retains its electrical conductivity despite being extended in way.

- Carbon Nanotubes and graphene (CNTs): These single atom thick carbon materials provide an amazing mixture of electrical conductivity optical transparency as well as physical strength. They are an ideal candidate for future generation Flexible Electronics.

- Liquid Metals Eutectic alloys made of gallium and indium melt at room temperature and may be enclosed in soft flexible microchannels that create flexible self healing and deformable interconnects.

3. Semiconducting Materials: The Flexible Brains

Transistors are the most fundamental switch that are the basis of every electronic. Making flexible transistors is one of the greatest successes and challenges in the area.

- Organic Semiconductors (OSCs): The carbon based molecules can dissolve to create chemical ink which can be printed at lower temperatures. Even though their efficiency (carrier mobility) is not as good as silicon its adequate for variety of applications such as the driving of display pixels as well as basic logic circuits. their flexibility provides an important benefit.

- Metal Oxide Thin Film Transistors (TFTs): Materials such as Indium Gallium Oxide (IGZO) are applied at low temperatures for the creation of high performance transparent TFTs that are fabricated with flexible substrates. IGZO is the main technology behind the breathtaking ultra high resolution and flexible OLED display screens that can be found in the top smartphones of today.

- Crystalline Silicon Flexible Forms Researchers have come up with ways to produce ultra thin elastic “nanoribbons” or “micro islands” made of monocrystalline silicon with high performance that are later transferred and joined to stretchable surface. The “island bridge” structure combines the demonstrated performance of silicon along with the deformability and mechanical properties of an elastic system. It is the very best of both worlds to create high performance Flexible Electronics.

4. Power Sources and Encapsulation

Flexible devices are useless without source of power that can be flexible. This has led to the invention of lithium ion batteries made from thin films which can bend and flex. Additionally wireless power transfer and energy harvesters that can generate electricity by absorbing lighting motion or heat are now essential to autonomous Flexible Electronics. Additionally encapsulation is an important yet often neglected part. The majority of metal oxide and organic materials are extremely susceptible to moisture and oxygen. An incredibly strong transparent and malleable barrier layer is necessary in order to guarantee long functional life for these products.

Production Flexible Electronics: The Shift from Silicon Valley to the Roll

Vacuum intensive high temperature and planar methods that are used to produce silicon chips tend to be incompatible with the delicate polymer substrates used in Flexible Electronics. This has led to drastic revision of the procedure shifting away from rigid wafers to constant high throughput printing processes that resemble newspaper press.

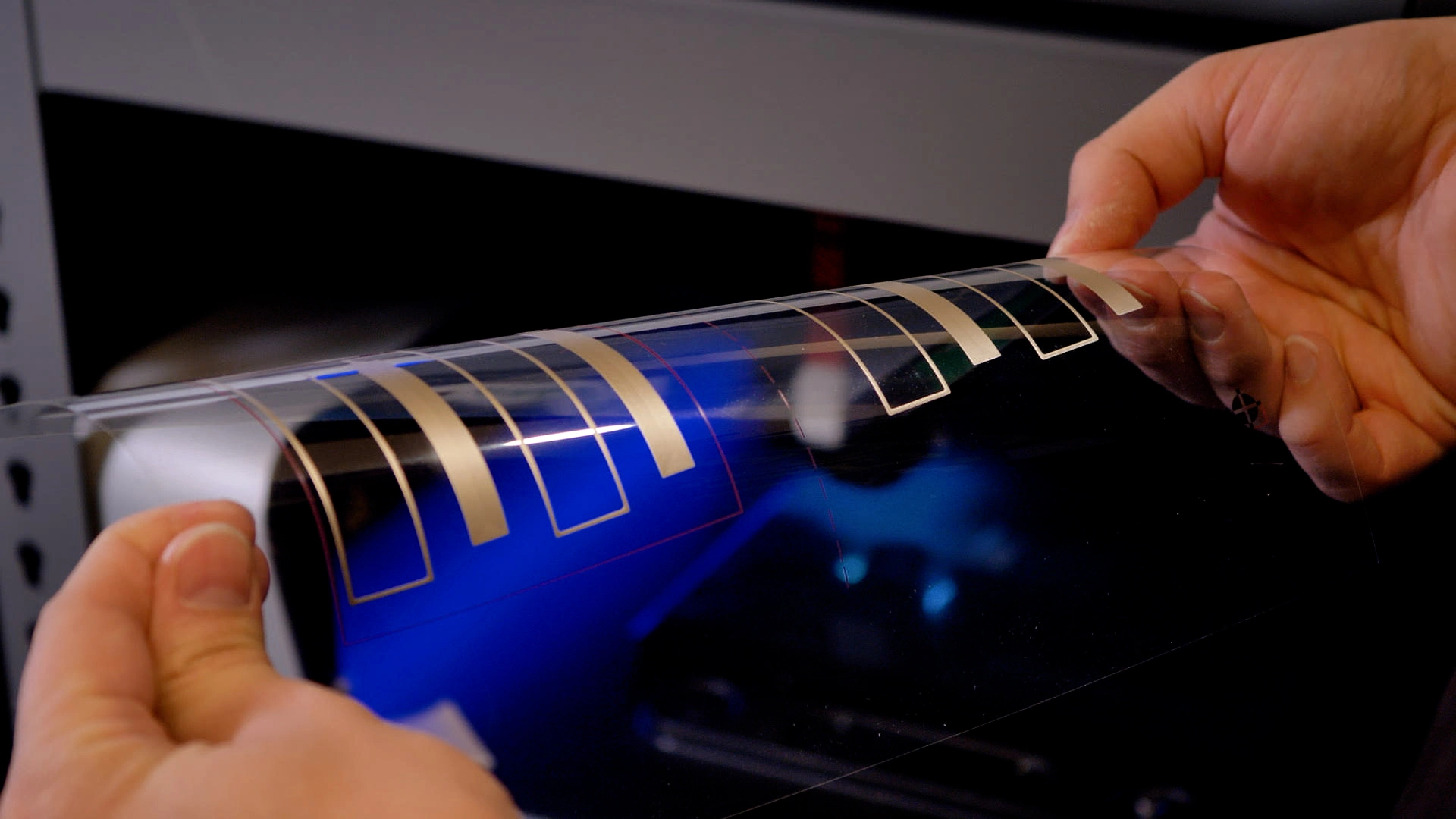

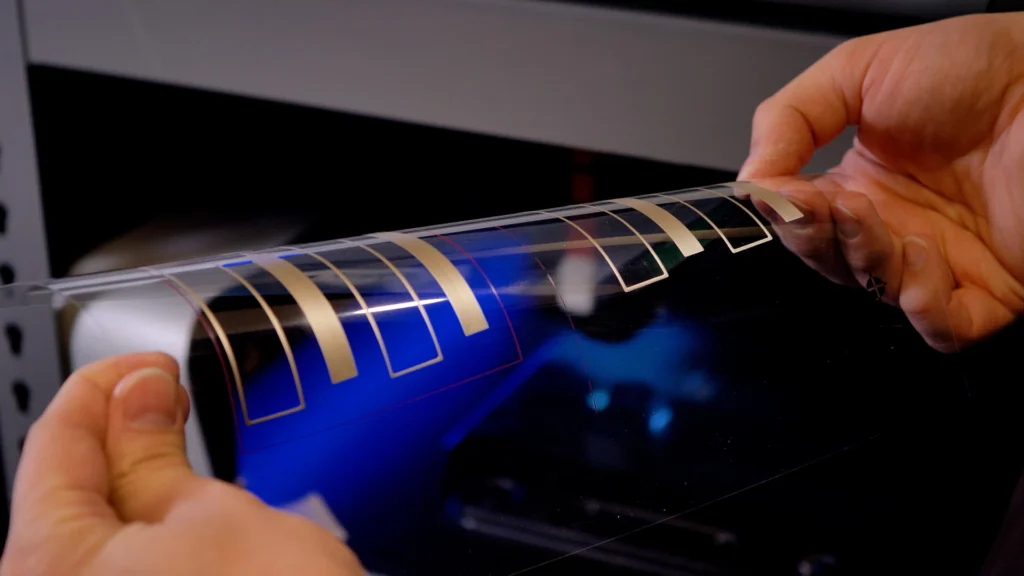

Roll to Roll (R2R) Processing

“Roll to Roll” (R2R) Processing is known as the ultimate solution for manufacturing low cost and high volume of Flexible Electronics. Through this method an entire roll of flexible substrate is cut and rolled through several curing printing and other processing facilities before being wound back onto the take up roll.

- The way it works: Each station performs one specific task. For instance one station could use the printing process of gravure or flexographic to place conductive traces on the floor and the other could deposit the semiconductor layer while another could treat the inks using UV radiation or heating.

- Benefits: R2R is an continuously and additive process creating massive economies of scale as well as drastically cutting down the price per device. It is the main technology that allows making things like elastic solar cells and RFID tags and sensors printed with number of millions. Its the future of production based Flexible Electronics.

Digital Additive Printing

Although R2R is ideal to produce large quantities of single model Digital printing techniques can be customized and allow rapid prototyping.

- Printing with Inkjets: Just like desktop printer the inkjet heads release tiny drops of inks that are functional (conductive and semiconducting) using high accuracy. This tool is versatile to create complicated multi layer circuits.

- Aerosol Jet Printing: This process produces very focused cloud of materials that can be precisely applied which allows for printing of extremely fine details (as as small as 10 millimeters) across flat and 3D surfaces. It is ideal for the creation of antennas sensors as well as interconnects for complex shapes.

Adapting Conventional Techniques

The principle of photolithography which is the basis for manufacturing silicon hasnt completely gone. Researchers have come up with “lift off” techniques where devices are initially manufactured on wafer that is rigid by using standard high resolution techniques followed by the thin and flexible device layer is removed and then transferred onto an elastic substrate. This enables the development of highly performance Flexible Electronics that utilize the accuracy of the existing infrastructure.

Application to Flexible Electronics: Weaving Technology into the Fabric of Life (2025)

In the year 2025 Flexible Electronics can no longer be confined to labs. Theyre enabling whole new generation of devices that are more intelligent with human interaction intuitive and intuitive like never before.

Wearable Technology and Healthcare

It is perhaps the most significant application field. Since it is able to conform to bodys shape Flexible Electronics can record physiological information in way that is extremely precise and comfortable.

- Electronic Skin (E Skin) and Smart patches. These are tiny skin like patches that be affixed to your body in order to monitor continuously vital indicators such as the heart rate (ECG) as well as temperature blood sugar levels and the level of stress (via an analysis of the sweat). By 2025 they will be shifting from hospitalization to fitness providing athletes with live performance information in real time and also allowing remote monitoring of patients older.

- Smart Textiles (E Textiles): Conductive fibers as well as printed sensors are woven directly into clothes. These create garments that be used to monitor posture track movement to aid in physical therapy and even incorporate heating elements or delicate visual displays.

- Soft Robotics and Prosthetics Flexible sensors give feedback about strain and pressure that give prosthetic hands an experience of touch permitting soft robots to communicate with their surroundings more securely and with greater care.

Flexible Displays and Lighting

Flexible Electronics have broken the stereotype of the rectangular flat screen.

- Foldable and Rollable devices: Foldable smartphones are at present in their fourth and third generations that have more durable displays and more refined mechanical systems. Beyond smartphones were experiencing the development of laptops that fold and amazing rollable TVs which can be tucked away to their pedestals when theyre not in use.

- Conformal Displays Displays are incorporated in the curvature of automobile dashboards and smart home appliances as well as wearable devices resulting in aesthetic and ergonomic interfaces.

- OLED Lighting Flexible Organic Light Emitting diode (OLED) Panels are thin as well as efficient and are able to be fabricated in any design. Designers and architects use them to design fittings for lighting that conform perfectly with ceilings and walls and are changing how we illuminate areas.

Internet of Things (IoT) and Smart Packaging

The dream of trillion connected devices calls for sensors that are inexpensive versatile lightweight and simple to install.

- Flexible Sensors Printing sensors at low cost for humidity temperature and pressure are able to be placed virtually anywhere. Temperature sensors that are flexible can be embedded into food packaging in order to check the chain of cold which will ensure the safety of your food and the quality.

- Intelligent Labels Packaging and Smart Labels Flexible Electronics make packaging more interactive. The printed NFC label on medication bottle could link the phone of patient to dose details and reminds. The label on wine bottle might flash or show the information upon touching.

- Structural Health Monitoring Sheets with large area flexible strain sensors can be fitted to bridges structures or wings of airplanes in order to constantly monitor fatigue and stress which allows for the maintenance of buildings in predictive manner and enhancing safety.

Key Advantages of Flexible Electronics

The motivation to design and use Flexible Electronics stems from an exclusive array of benefits over rigid counterparts.

- Unique Form Factors The capability to bend fold and stretch makes it possible for devices to can be folded up and as skin or integrated into items of any shape.

- Robustness and Durability: Flexible devices are by nature more robust to shock and vibrations than brittle or rigid electronics. The impact of dropping device made from the flexibility of substrate is much less likely to lead to an unintentional failure.

- Slim and Light: By eliminating heavy board rigid circuits and enclosures Flexible Electronics can result in devices that are considerably smaller and lighter. This is crucial for wearables and aerospace related applications.

- The potential for low cost high volume manufacturing: Print based manufacturing R2R methods promise to significantly lower costs of manufacturing electronic devices specifically for applications that require large areas such as solar cells and sensors.

Challenges and Future Horizons for Flexible Electronics

Despite all the progress made in the direction of the world of fully flexible technology faces obstacles to conquer. The group that is working on Flexible Electronics is active in addressing these issues.

Current Challenges

- Lifespan and Reliability: The materials used to make Flexible Electronics specifically organics are susceptible to degradation as time passes when exposed to humidity and air. In addition the repeated stress may cause wear and eventual failure. The improvement of the longevity of these devices is the important aspect of.

- Power Management The powering of these devices is an enormous problem. Flexible batteries have less energy density that their rigid counterparts and the integration of power sources without losing flexibility.

- System Integration The current world isnt fully flexible at the moment. One of the biggest engineering challenges is the development of reliable and durable ways for connecting flexible circuits with the silicon chips that are rigid and other components which still offer the computing power that is high performance.

- Manufacturing Scalability While R2R processing offers tremendous potential scaling advanced materials and intricate designs from the laboratory into high volume production is an intricate and costly task.

The Future is Stretchable Transient and Self Healing

This cutting edge research pushes the limits of the capabilities of Flexible Electronics is able to achieve.

- Flexible Electronics: The next technology is to create electronic devices that arent just stretchable but actually elastic as skin. This will allow for even better bio integration that is seamless for medical monitoring as well as prosthetics.

- Transient Electronics Researchers are creating products made of biodegradable substances which are intended to work for certain time that then completely dissolve. This could be used to create short term medical implants that dont need surgical procedure for removal or as environmental sensors that dont leave evidence.

- Self Healing Electronics Inspired by the biology of life researchers have developed materials with embedded microcapsules of healing substances that automatically fix cracks or breaks in conductor pathways. This will result in incredible durable and long lasting gadgets.

A New Shape for Technology

Flexible Electronics represent more than just an improvement in technology. They represent fundamentally reimagining human interaction with the world of technology.

The hard edged rigid gadgets that defined the past fifty years are now beginning to disappear into the world and become more supple adaptive and linked to our lives. The age of conforming to technology has come to an end; and the time of technology that conforms to our needs has just begun.

The impact of this transformation will be visible all around us in the vivid folding screens that we carry inside our pockets the sophisticated sensors we wear in our clothes as well as those life saving devices for medical use on our skin.

Its far from completed and some significant issues for manufacturing and materials research are still to come. The path ahead is clear. Flexible Electronics do not represent niche. They represent the future.

Theyre weaving computation into the foundation of our being and creating future where technology isnt just an item we carry around but instead an unassailable extension of us. The future is flexible and is being constructed now by using Flexible Electronics.

- Digital Health Guide 2025: Navigating the Future of Wellness

- Picsart AI Photo Editor Video: The Ultimate Guide to Mastering Visual Content in 2025

- Green Nitrogen Fixation: The Ultimate Guide to Sustainable Future (2025)

- Flexible Electronics: The Ultimate Guide to Bendable Wearable Future in 2025

- Elastocalorics: The Ultimate Guide to the Future of Cooling in 2025