The word Elastocalorics refers to the class of material and their thermodynamic effects. In the core of the effect of the elastocaloric phenomenon is a changes in the temperature of materials when subjected to a mechanical strain. It is a part of the larger category of “caloric” effects

which also comprises magnetocalorics (response to magnetic fields) electrocalorics (response to electrical field) and barocalorics (response to the hydrostatic pressure). They are just a few of them. Elastocalorics are emerging to be one of the best ways to develop practical alternatives for cooling that are commercially viable.

Consider a basic rubber band. If you stretch it fast and then apply pressure onto your lip youll notice it getting warmer. As you relax it the sensation is cool. This is a basic illustration of the elastocaloric effects. But the new materials

that are being created for use in real world applications display changes in temperature that are several times greater than rubber band. The secret lies in the use of special “superelastic” materials most notably form memory alloys (SMAs).

They can go through a an irreversible transition from solid state to phase upon application of pressure. This internal structural rearrangement that changes from a chaotic state to more organized one which releases a substantial amounts of heat.

Once the stress is gone the material returns to its initial state absorbing the heat of its surroundings and creating a powerful cooling effects.

It is this huge reversible temperature reaction that is the Elastocalorics an important factor in refrigeration. The research field of Elastocalorics is thus focused in identifying and constructing the materials into useful coolants and heat pumps.

Physics Behind the Elastocaloric Effect

To fully comprehend the capabilities of Elastocalorics you must examine the tiny modifications that occur within the materials crystal lattice. The secret to this technique isnt really magic; it is a fascinating interaction between the thermodynamics of materials science and mechanics.

The Martensitic Transformation: The Engine of Change

The primary mechanism for the high performance Elastocalorics is the martensitic reversible phase transformation. Shape memory alloys the principal material used in two crystals that are solid states:

- Austenite Phase: This is the parent phase with high temperatures. It generally has a more ornate geometric crystal structure (often cube). This type of material is comparatively malleable and soft.

- Martensite Phase It is the lowest temperature phase. Its less symmetric and more complicated crystal structure (e.g. Orthorhombic or monoclinic). It is usually more hard and less ductile when in this form.

In the case of conventional materials phase change involves a the change of temperature (like melting of ice to water). For shape memory alloys this change can be caused not just through temperature but also through mechanical tension. This is the reason for the elastocaloric effects.

If an external strain (like compression or tension) is applied to the substance in its austenite state it causes the crystals lattice to the martensite stage. It is an exothermic reaction. Atoms are rearranged into a more organized configurations which results in a an increase in energy (a measurement that measures disorder). Based on the thermodynamic laws this reduction in entropy has to be accompanied with releases of energy into the surroundings. This energy release is referred to as latent heat and its size determines the strength of the elastocaloric effects are. Material with a large amount of latent heat of conversion is a likely to be a good potential candidate for Elastocalorics.

In contrast when the stress is eliminated the material is unstable in the martensite stage and then spontaneously returns to its austenite form. The reverse transformation can be described as exothermic. The crystals lattice reverts to its disordered form which increases its energy density. In order to do that it has to absorb a large quantity of heat from its surrounding. The absorption of heat creates the cooling result. The elastocaloric cooling process harnesses this process by putting the substance into contact with the surface or object that is which is cooling during this stage. The beauty of Elastocalorics comes from the mechanical devices to control the super efficient reversible energy pumping system.

Key Elastocaloric Materials of 2025

The effectiveness of any elastocaloric component is determined by the physical properties of its active component. In 2025 research is concentrated on identifying and optimizing material that is durable and efficient and affordable.

Nickel Titanium (NiTi) Alloys: The Gold Standard

Nickel Titanium alloys also known as Nitinol are among the most extensively studied and top performance elastocaloric substances up to now. They serve as the standard for all other materials are compared.

- Property: NiTi exhibits very large and reliable elastocaloric impact that has adiabatic temperature variations (DTad) as high as 25K reported during experiments. It is extremely elastic meaning it is capable of being stretched to a significant extent (up up to 8 percent) but still be able to be able to return to its initial shape.

- Benefits: The most significant benefit is its remarkable resistance to fatigue. NiTi is able to be used hundreds of thousands and millions of times without causing any significant loss in its efficiency. This endurance is essential in any real world cooling device that must be running for years. That makes NiTi the top material used for the development of Elastocalorics prototypes.

- Negatives: The major drawbacks of NiTi is the high price because of the high priced raw material (titanium) as well as the complex process and a significant inherent Hysteresis. Hysteresis refers to the variation in pressure required to trigger the forward and reverse transforms and it is a sign of lost energy (waste heat) which decreases the overall performance of the cooling process.

Copper Based Shape Memory Alloys

Copper alloys like Cu Zn Al and Cu Al Ni have been explored as a cheaper alternatives for NiTi.

- Properties: They are able to exhibit strong elastocaloric effect often comparable to NiTi.

- Benefits: The main benefit is their cost. They are less expensive and plentiful as compared to NiTi and are therefore more suitable for applications in the mass market that are driven by cost.

- Negatives: The main weakness of copper based SMAs is their fragile longevity in fatigue. Theyre brittle and susceptible to breakage after a small quantity of cycles particularly when they are polycrystalline (like sheets or wires). They are not suitable for application in equipment that requires the use of long term operations. Research on Elastocalorics is focused on microstructural design and composites to increase their mechanical strength.

Iron Based Alloys and Other Emerging Systems

A new class of materials is continuously being studied to discover an optimal balance of high performance cost and long lasting. Iron based SMAs (e.g. Fe Pd) and high entropy metals are gaining attention as fascinating research subjects. Another fascinating field of research of Elastocalorics can be found in the world of polymers.

- Polymer based Elastocalorics Some polymers in particular the natural rubbers and neoprene are able to have a notable elastocaloric impact. Even though their temperature variations are typically less than that of SMAs theyre extremely cheap light and can cycle for a long time without fatigue. In 2025 the focus of research is molecular engineering and developing composite structures that enhance the caloric performance of these polymers potentially opening the doors to flexible and cheap cooling solutions. Development of high performance polymer Elastocalorics could lead to a major technological breakthrough.

Designing Elastocaloric Cooling Systems: From Lab to Application

A great material is just part of the problem. The real challenge in engineering is to design a device that harnesses the materials properties to move heat. This is the primary job of engineers who work in Elastocalorics.

Components of an Elastocaloric Heat Pump

The typical elastocaloric cooling device similar to a conventional refrigerator runs by a thermodynamic cycle. The most important components include:

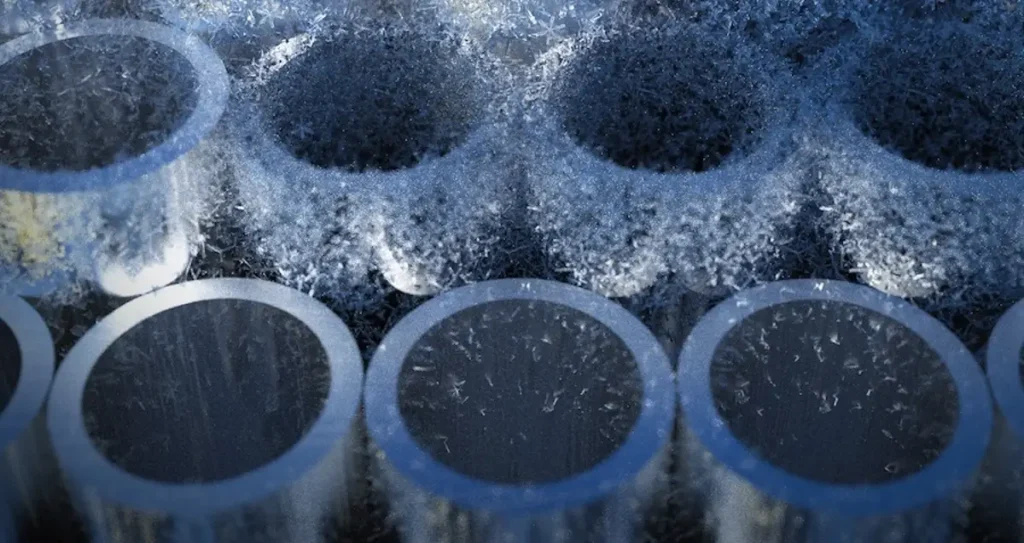

- The Elastocaloric Materials: This is at the core of the system. It is typically as pipes or wires for maximum surface space.

- An Actuation Mechanical System A Mechanical Actuation System: This system is that is responsible for imposing and releasing pressure on the product. It can be a set that includes motors and cams to tension hydraulic press that is used for compression or the bending actuator.

- The Heat Exchangers are essential to transfer heat through and out of the elastocaloric substance. In general fluid (like air or water) is utilized as a the medium for heat transfer.

- The heat transfer fluid Circuit The use of fans or pumps can be used to circulate water between the elastic materials along with the cold and hot reservoirs (i.e. the inside of a refrigerator as well as the air outside).

The Active Regeneration Cycle

In order to achieve a temperature range greater than the change in temperature of the substance itself The most modern elastocaloric designs employ a the principle known as Active Magnetic Regeneration (AMR) specifically designed for the elastocaloric cases (and hence is often referred to as the Active Elastocaloric Regenerator (AER)).

Heres how the an AER cycle operates:

- The application of stress (Heating) A elastic material (e.g. tubes of NiTi) can be stretched. It gets hot due to the transformation of phase.

- Hot Fluid Flow The heat transfer fluid flows through the material from one side of the material toward its hot end. The fluid absorbs the thermal energy that is released by the materials and then transports it through the heat exchanger where its released out into the surrounding.

- Stress removal (Cooling) Amount of stress on the elastocaloric materials can be released. This material then snaps its austenite phase which absorbs the heat before changing into cold.

- Cold Fluid Flow: The liquid is now being pumped in opposite direction from the hot to its cold counterpart. While it is flowing through the cold materials the fluid sheds its heat and is then cold. The chilled fluid then gets transported to the cold exchanger which provides cooling to the area of interest.

Utilizing the fluid to produce a temperature gradient over the entire length of the bed this permits the device to reach a cooling spans that are more than the inherent DTad. Design and optimization of the AER devices is crucial to the performance of Elastocalorics.

2025 Prototype Designs

Engineers are exploring different device designs to increase the efficiency of their devices and to reduce fatigue. A few of the innovative concepts being studied for 2025 include:

- Tensile Cyclers: These gadgets make use of wire bundles or thin sheets which can be stretched and released cyclically. Theyre mechanically straightforward however they are susceptible to stress concentrations on the areas of contact.

- Compressive Systems: Elastocaloric bulk materials are compressed cyclically. They can withstand greater forces but they typically have slower thermal transfer because of lower proportions of surface area to volume.

- The Torsional and Bending Actuators: This innovative approach aims to decrease fatigue of the material and help create devices with smaller footprints.

- 3D printed structures 3D printed structures are being utilized to design sophisticated porous elastocaloric regenerators that have optimised geometries to facilitate the flow of heat and fluids. This is a significant advancement in the area of Elastocalorics.

Applications and Future Prospects of Elastocalorics

The possibilities for applications of efficient solid state cooling are extensive and transformational. Elastocalorics technology isnt just a an alternative to existing systems it opens up entirely different possibilities.

HVAC and Refrigeration

It is by far the biggest and most evident market. Elastocaloric heating systems could be used to replace the compressors condenser and the evaporator inside your the refrigerator or home air conditioner. There are many benefits to this:

- More Efficiency: Projections show that the most efficient elastocaloric system might be 20% 30 percent more efficient than most efficient vapor compression systems leading to substantial energy savings.

- Environmental Safety: Complete absorption of the highly GWP refrigerants is a huge success for climate protection.

- Silent Operation: Solid state systems will be almost quiet compared to the sound of a conventional compressor.

Electronics Cooling

With microchips becoming increasingly efficient and packed with power the removal of the heat that is wasted can be a major bottleneck. Elastocalorics may provide extremely effective and localized cooling solutions to GPUs CPUs and various other electronic devices with high power possibly integrated directly into circuit boards or chips.

Medical and Scientific Applications

A variety of laboratory and medical applications need precise and secure storage of samples medicine and vaccines. The small size and durability of solid state Elastocalorics makes them a great choice for mobile medical coolers and highly stable lab refrigerators.

Automotive Climate Control

The move to electric vehicles (EVs) puts a premium on efficiency as the air conditioner will significantly decrease the vehicles range. A highly efficient elastocaloric device will provide cooling to the cabin at less power consumption thereby increasing the range of driving and enhancing general vehicle performance. Development of automotive grade Elastocalorics is a major research objective.

Waste Heat Recovery

The elastocaloric effect can be reversed. Like applying stress to cause temperature changes applying a the temperature can cause mechanical effort. The elastocaloric device could possibly be used in the form of engines that convert low grade wasted heat generated by factories or power plants to electricity thereby enhancing their eco friendly potential.

Benefits from Elastocalorics Over Conventional Cooling

In direct comparison to current vapor compression technology the argument for Elastocalorics can be extremely convincing.

- Zero Global Warming Potential (GWP) Active substances are solid and stable. The materials do not have refrigerants in fluids that leak into the air. This could be the biggest ecological benefit.

- Superior Theoretical Efficiency coefficient of Performance (COP) measure of the efficiency of cooling in elastic systems is likely to be much superior to vapor compression cycles. This directly translates into lower power consumption and lower operational cost.

- The High Cooling Power Density Materials that are elastic can produce a huge quantities of heat relative to their weight and size making them more compact and lighter design of devices.

- Dual Cooling and Heating Similar to any other heat pump an elastocaloric unit is able to be used for cooling as well as heating. It is often used better than conventional electronic resistance heaters.

- Solid state systems have fewer moving parts which can lead to longer life spans and less maintenance demands compared with mechanical compressor. It is a promise that reliable Elastocalorics is a major driving force behind the development of.

Challenges and Hurdles on the Road to Commercialization

Despite the huge potential many important challenges need to be addressed prior to purchasing an elastocaloric AC at the local hardware store. The sector of Elastocalorics is working to address these challenges.

- Lifespan and Material Fatigue The biggest issue. Systems for cooling must function continuously for billions of cycles throughout a time spans of 10 to 20 years. Although NiTi has excellent properties but it is susceptible to degradation over the course of time. Making sure that the material has long term functionality and mechanical stability of the product is essential. Researchers are currently working on novel coatings for alloys as well as annealing techniques that can increase fatigue lifetime.

- Effective Heat Transfer: transferring the heat efficiently and rapidly between solid elastocaloric materials and the fluid used for heat transfer is a major engineering challenge. The rate of heat transfer is often a factor that limits the frequency of cycling and consequently the capacity of cooling the device. This is why the development of regenerators that have a large surface area and high thermal conductivity is crucial for efficient Elastocalorics.

- Hysteresis Losses: As stated Hysteresis is the result of wasted energy which is manifested as heat and reduces the overall efficiency of the system. The reduction of hysteresis via materials engineering (e.g. through the creation of solid interfaces between the martensite and austenite phases) is an important area in material science research.

- Production and Costs Material Performance: Materials that perform well such as NiTi are costly to make. Finding cost effective scalable manufacturing processes for the production of Elastocaloric parts with the intricate designs required by high end regenerators is vital to commercial viability. The price of Elastocalorics need to be competitive in order in order to guarantee market adoption.

2025 Research Frontier: Pushing the Boundaries of Elastocalorics

The science of Elastocalorics isnt static at all. The Elastocalorics research field in 2025 is dynamic and multidisciplinary that is undergoing breakthroughs in the nexus of materials science engineering as well as data science.

AI and Machine Learning for Materials Discovery

Researchers are using computer machines and machine learning techniques to increase the speed of discovery of novel elastocaloric material. In analyzing vast databases of alloy compositions AI will be able to predict which alloys tend to exhibit desirable characteristics (large latent heat low hysteresis and high stability) that allows researchers to narrow their research efforts on most promising materials.

Advanced Manufacturing and Composites

The 3D printer (additive manufacturing) can allow the construction of complex single piece regenerator designs that were once impossible to design. This makes it possible to optimize the design of the fluid channels as well as the distribution of materials to maximize heat transfer. In addition researchers are working on the elastocaloric and elastomeric composites such as embed SMA particles into polymer matrix to blend the superior performance of the alloy and the elasticity and strength that the polymer provides.

Novel Device Architectures

The goal is to move away from simply demonstration systems to more optimized and integrated system. It is also exploring new ways to actuate which are more effective and less harsh on the materials and also constructing efficient and compact heat exchangers. Future development of Elastocalorics relies on the level of innovation at this system.

A Cool Change is Coming

The time when we rely solely on vapor compression for cooling requirements is coming to a an end. Environmental and energy expenses are too much for a world that is warming. Elastocalorics are more than an incremental enhancement and are a an entire paradigm shift in the way we view the management of heat. The technology can lead us to a the future of cooling that is efficient eco friendly and green.

The path from lab discovery to the commercialization of a product can be long and brimming with difficulties including achieving the highest durability of materials to creating cost effective solutions.

However the advancements in the sector of Elastocalorics during the last decade has been remarkable. The science behind it is solid and the essential material has been discovered and the pathways to engineering become clearer.

In 2025 it is not a matter of whether elastocaloric cooling is going to become a the norm but instead what happens when. Thanks to the amazing physics of advanced materials Elastocalorics will bring an exciting change that benefits our pockets and most important of all the planet. Future cooling technology is proven and the name of it is Elastocalorics.

- Digital Health Guide 2025: Navigating the Future of Wellness

- Picsart AI Photo Editor Video: The Ultimate Guide to Mastering Visual Content in 2025

- Green Nitrogen Fixation: The Ultimate Guide to Sustainable Future (2025)

- Flexible Electronics: The Ultimate Guide to Bendable Wearable Future in 2025

- Elastocalorics: The Ultimate Guide to the Future of Cooling in 2025